What Brands Should Know About Silicone,Sructural for Adult Toy

What Brands Should Know About Silicone,Sructural for Adult Product

Problem: ustomizing silicone adult toys requires balancing material properties, structural integrity, and user experience—yet most brands lack actionable insights to avoid costly mistakes.

Without understanding how silicone hardness interacts with product design, companies risk creating uncomfortable products, facing production delays, or overspending on incompatible materials.

Solution: This guide distills 7 years of industry expertise into actionable strategies for aligning material selection, structural engineering, and market demands.

For brands, retailers, and wholesalers, successful silicone adult toy customization hinges on three pillars:

1. Material Selection: Shore hardness (-20° to 45°) dictates softness, structural support, and moldability.2. Structural Design: ABS + silicone hybrids optimize cost, while full-liquid silicone maximizes realism.

3. Market Alignment: Premium markets (US/EU) prioritize FDA-certified, body-safe materials over low-cost alternatives.

Please keep reading, Below, we’ll decode factory trade secrets about silicone grades, reveal cost/quality tradeoffs in structural designs, and share data-driven strategies to position your product competitively.

Key Considerations for Custom Silicone Adult Toys

1. How Does Silicone Hardness Impact Product Performance?

Shore Hardness Scale Demystified

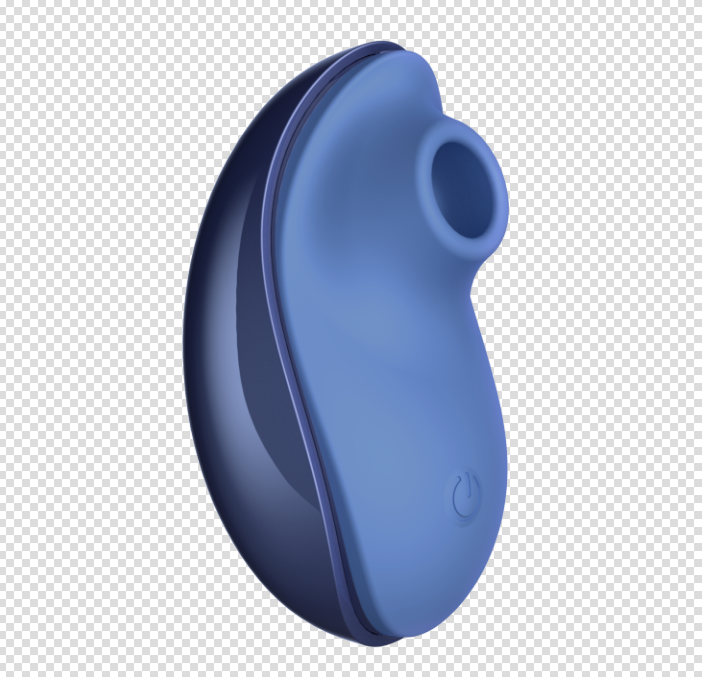

-20° to 0°: Ultra-soft (ideal for realistic dildos/skin-like sleeves)15°–35°: Medium-firm (best for vibrators, prostate massagers, clitoral stimulators)

Critical Insights:

User Comfort vs. Durability: Lower Shore values (0°–15°) mimic human skin but increase mold defects (e.g., silicone burrs). Higher values (25°+) reduce post-production labor but may compromise realism.Liquid vs. Solid Silicone:

Liquid Silicone Rubber (LSR): Seamless finishes, FDA-compliant, higher waste (20–35° range common).Solid Silicone: Cost-effective for ABS hybrids but limited to ≥25° hardness to prevent tearing during demolding.

Pro Tip: Always request factory samples in your target Shore hardness before bulk production.

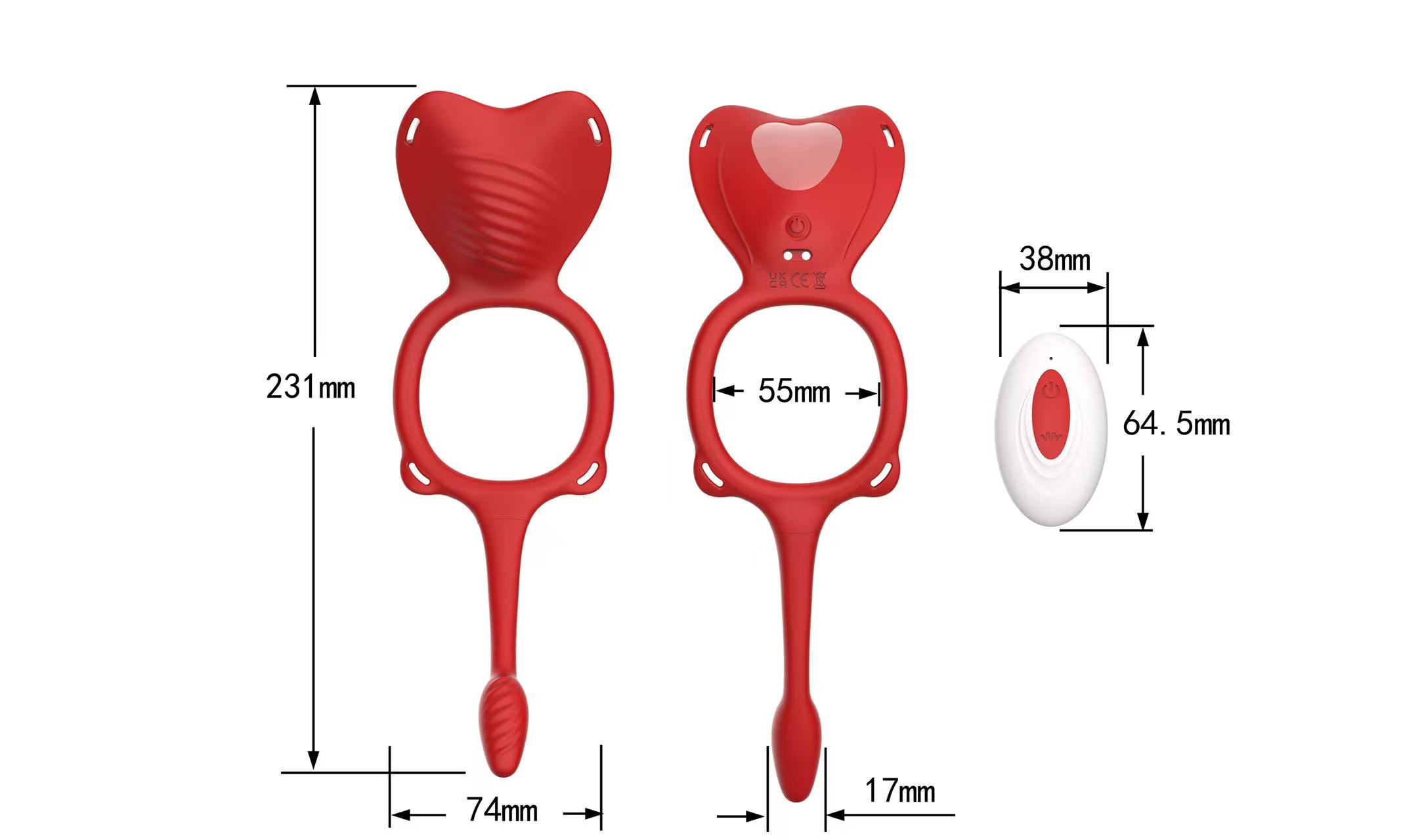

2. What Structural Designs Balance Cost and Quality?

Top 3 Adult Toy Architectures

| Design | Pros | Cons | Ideal For |

|---|---|---|---|

| ABS + Solid Silicone | Low cost, easy repairs | Less realistic feel | Budget vibrators ($15–$30 |

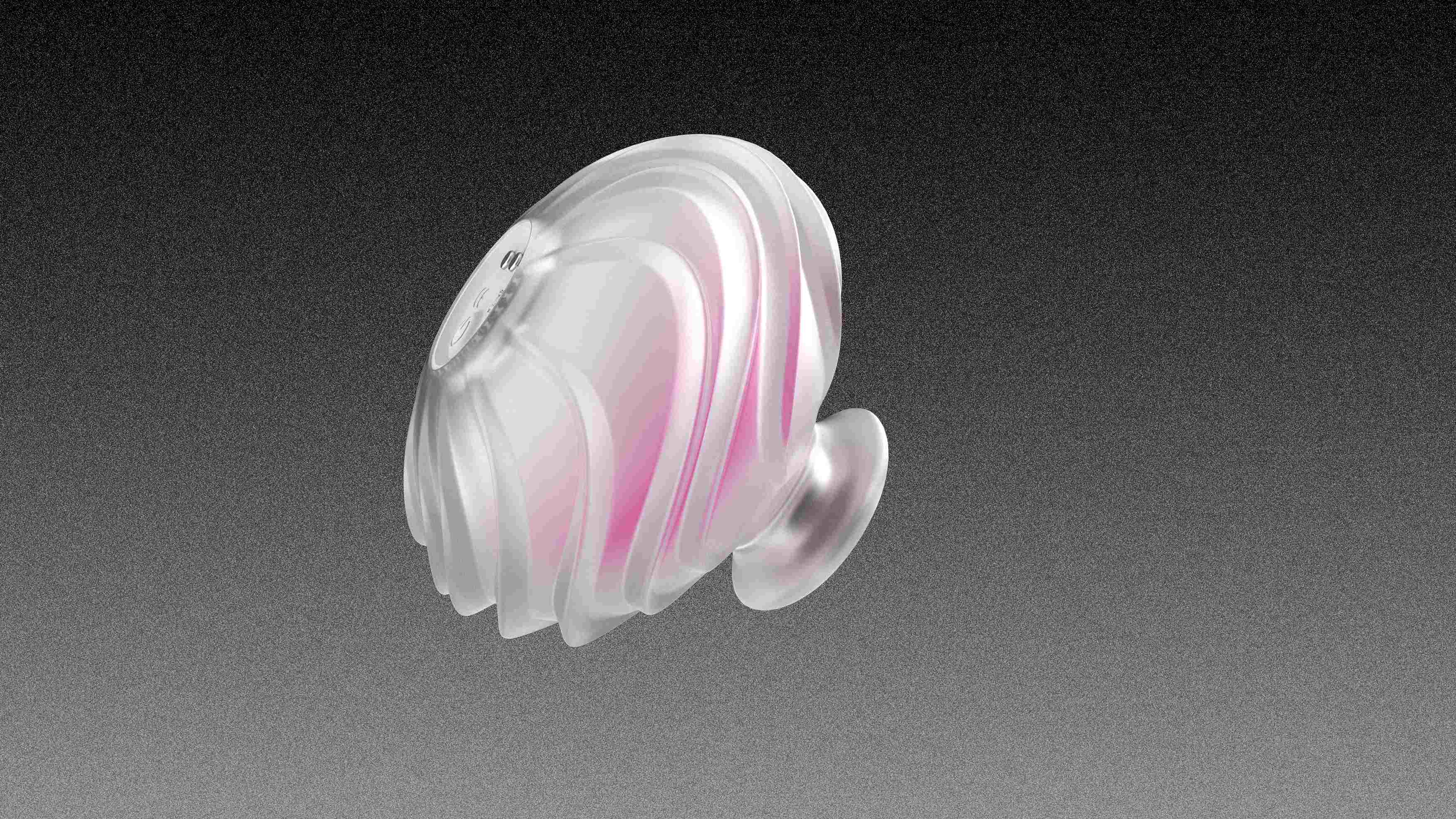

| Full-Liquid Silicone | Premium tactile experience | High material waste (30%+) | Luxury brands ($50–$150) |

| Hybrid (ABS + LSR) | Balanced cost/feel | Complex assembly | Mid-range products ($30–$70) |

Thickness Guidelines:

Sleeves: 1.5–2mm thickness for tear resistance (25°–35° silicone).

Dual-Layer Dildos: 20° inner core + 0° outer layer maximizes realism while preventing sagging.

Factory Red Flag: Suppliers pushing ≤20° solid silicone for sleeves often hide high defect rates (up to 15% post-processing).

3. How to Align Design with Market Demand?

Regional Preferences (2023 Data)

North America/Europe: 78% prioritize body-safe, phthalate-free materials (FDA/CE certifications mandatory).Asia-Pacific: 63% favor compact, discreet designs with mid-tier pricing ($20–$50).

Brand Positioning Strategies:

Premium Brands: Use full-LSR designs with medical-grade certifications. Highlight Shore hardness in marketing (e.g., “10° Skin-Real™ Silicone”).Mass Market: Opt for ABS hybrids with 25°–30° sleeves. Emphasize waterproofing and warranty terms.

Case Study: A US retailer increased repeat purchases by 41% after switching from TPE to dual-layer LSR (15° inner/5° outer) for G-spot vibrators.

Final Checklist Before Production

1. Verify FDA/ROHS certifications for all silicone batches.2. Test prototypes across Shore hardness gradients (±5°).

3. Audit factory defect rates for your chosen material/structure combo.

Conclusion:

Silicone hardness and structural design directly determine your product’s comfort, durability, and market success. By mastering these variables, brands can avoid 80% of customization pitfalls—saving time, budgets, and reputations.