What Defines a Safe Silicone Dildo? Inside the Manufacturing Process

Problem: Consumers often wonder why some silicone dildos feel safer or last longer than others. With rising concerns about cheap, non-body-safe materials in adult toys, knowing how a high-quality product is made becomes critical.

Solution: Understanding the science-driven manufacturing process—from raw materials to final testing—ensures you’re investing in a product that prioritizes safety, durability, and pleasure.

A body-safe silicone dildo is defined by rigorous manufacturing steps: medical-grade material selection, precision molding, ontrolled curing, and multi-stage quality inspections. These processes ensure compliance with international safety standards (like ISO 10993 and FDA guidelines) while delivering a product that balances aesthetics, comfort, and functionality.

Curious how factories turn liquid silicone into a premium, hypoallergenic toy? Let’s dissect the behind-the-scenes workflow trusted by ethical manufacturers.

1. Why Is Medical-Grade Silicone Non-Negotiable?

Not all silicones are equal. Medical-grade silicone undergoes strict certification to guarantee:Non-toxicity: Free from phthalates, latex, and heavy metals.

Hypoallergenic properties: Safe for sensitive skin.

Temperature resistance: Retains shape and softness even with repeated sterilization.

Industry Insight: Reputable manufacturers source silicone with ISO 10993 certification, which tests biocompatibility for prolonged skin contact.

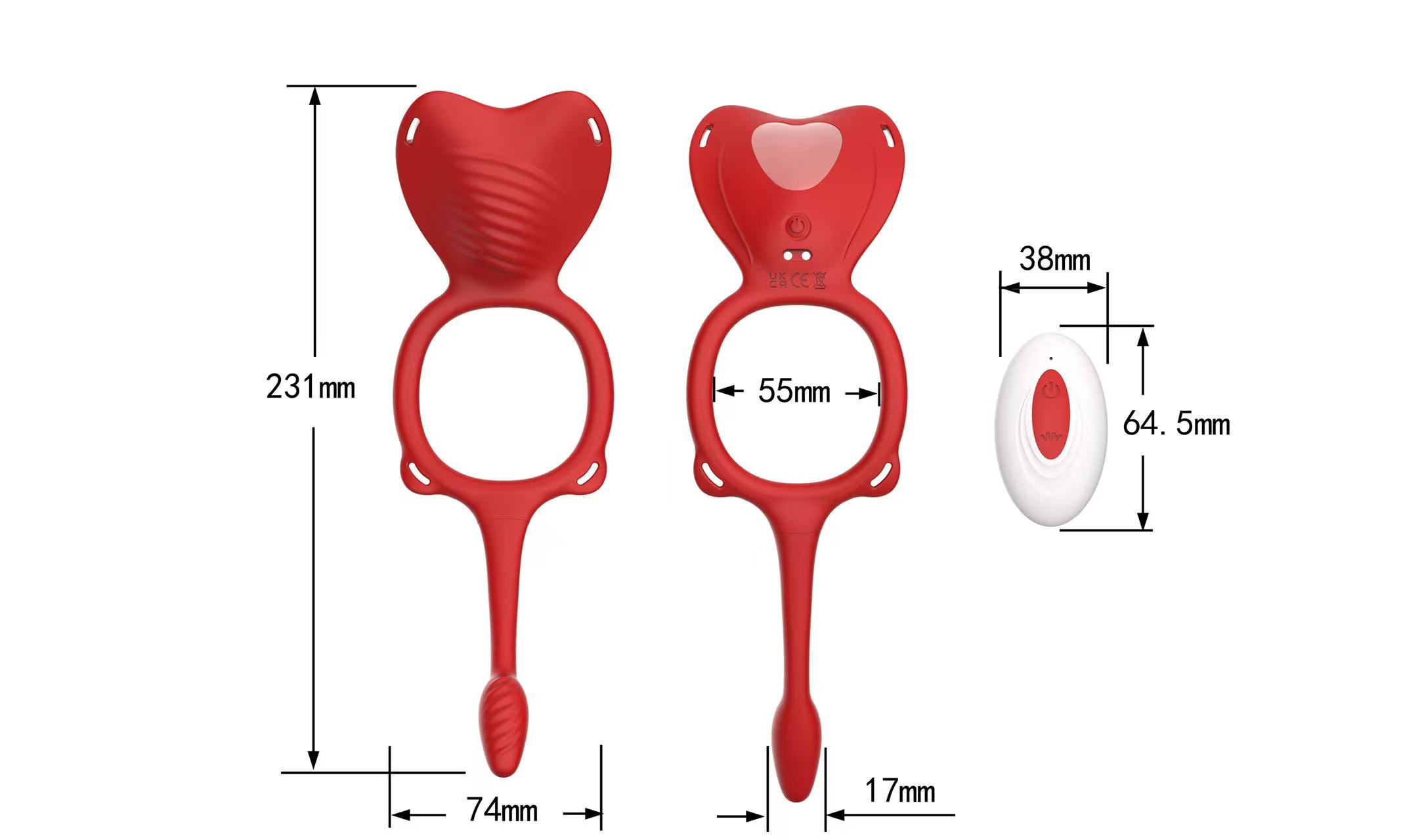

2. How Does Digital Design Improve Safety?

Modern dildo production starts with 3D modeling software instead of hand-sculpting. Benefits include:Ergonomic precision: Curvature, texture, and proportions are optimized for comfort.

Reduced human error: Laser scans detect imperfections before prototyping.

Customization: Adaptable to diverse user needs (e.g., angled tips for G-spot stimulation).

3. What Makes a Mold "High-Risk" or "Low-Risk"?

Mold quality directly impacts safety. Key considerations:Material: Platinum-cure silicone molds prevent chemical leaching.

Venting systems: Eliminate air pockets that cause weak spots or bacterial traps.

Post-use sterilization: Molds are autoclaved between batches to avoid cross-contamination.

Pro Tip: Avoid toys with visible seams—they indicate poor mold alignment, which can harbor microbes.

4. Why Do Factories Use Vacuum Chambers for Silicone?

Air bubbles aren’t just cosmetic flaws—they weaken structural integrity. Factories tackle this by:Degassing: Silicone is mixed in vacuum chambers to remove trapped air.

Pressure casting: Liquid silicone is injected into molds under controlled pressure for even distribution.

5. How Long Should Silicone Cure for Optimal Safety?

Rushing curing risks incomplete polymerization (leading to sticky or porous surfaces). Best practices:24-48 hours: Room-temperature curing ensures thorough hardening.

Post-cure baking: Some brands bake dildos at 150°F (65°C) to enhance tear resistance.

6. What Tests Guarantee a Dildo Is Body-Safe?

Post-production inspections are exhaustive:Tensile testing: Stretches silicone to verify it withstands 300-500% elongation without tearing.

Porosity checks: Submersion in dye detects microscopic holes that could trap bacteria.

Flex cycles: Bent 1,000+ times to mimic long-term use.

Consumer Tip: Look for brands that publish third-party lab results.

7. How Does Packaging Prevent Contamination?

Even flawless dildos can be compromised by poor packaging. Safe brands use:Antimicrobial pouches: Prevent mold during shipping/storage.

UV-resistant boxes: Protect silicone from degrading in light.

Sealed sterilization: Gamma irradiation eliminates pathogens before sealing.